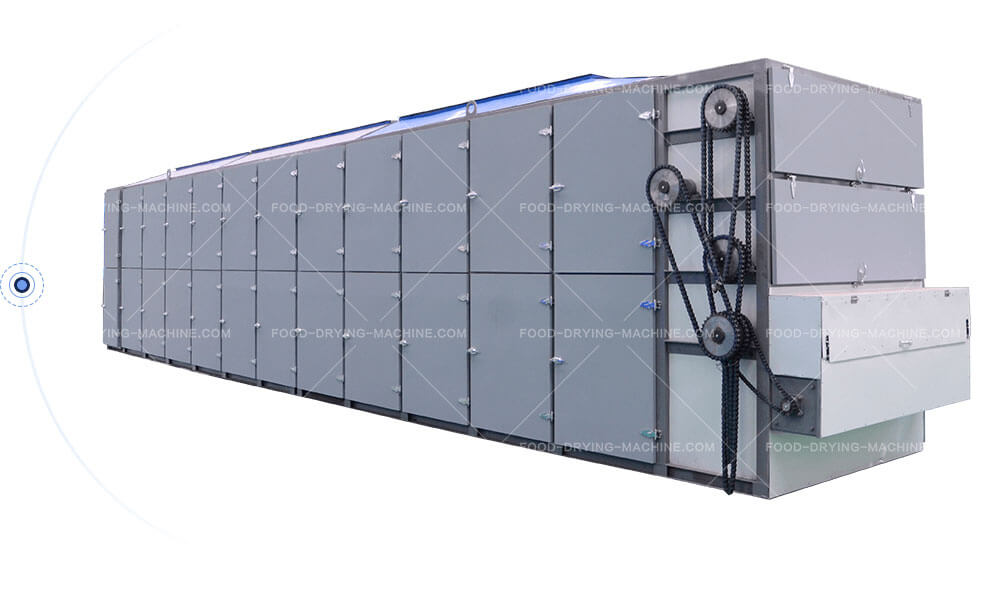

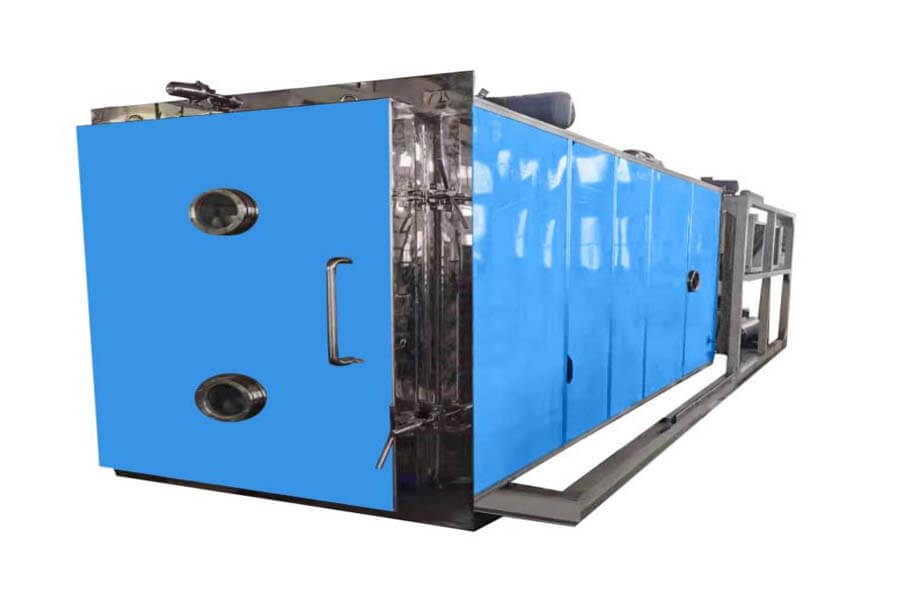

Industrial Heat Pump Food Drying Machine Introduction

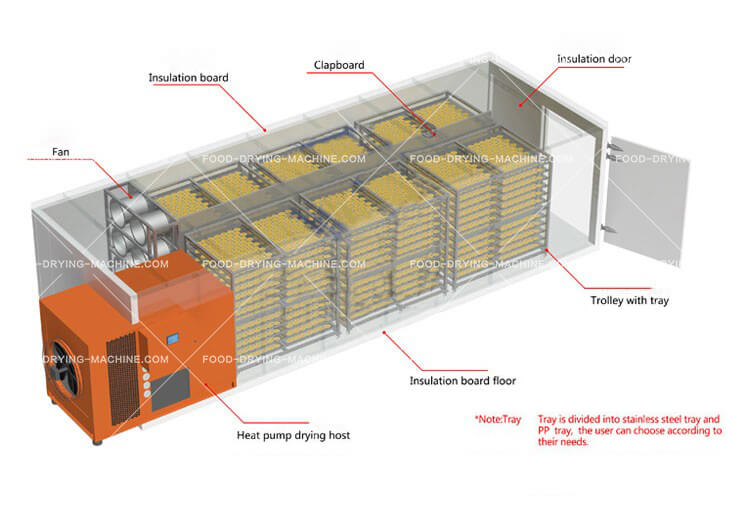

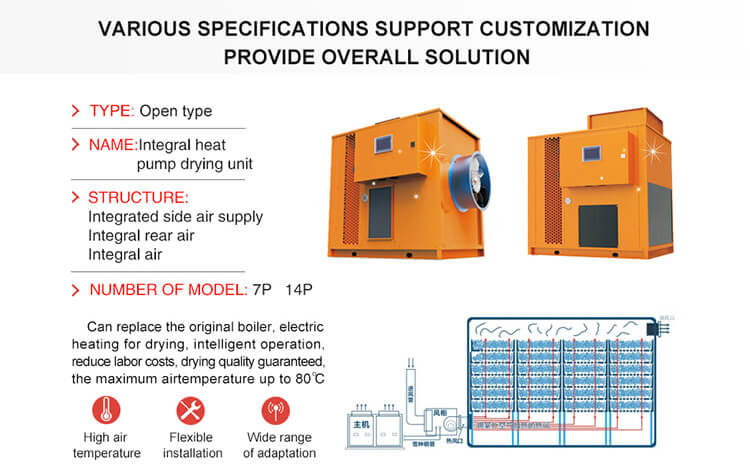

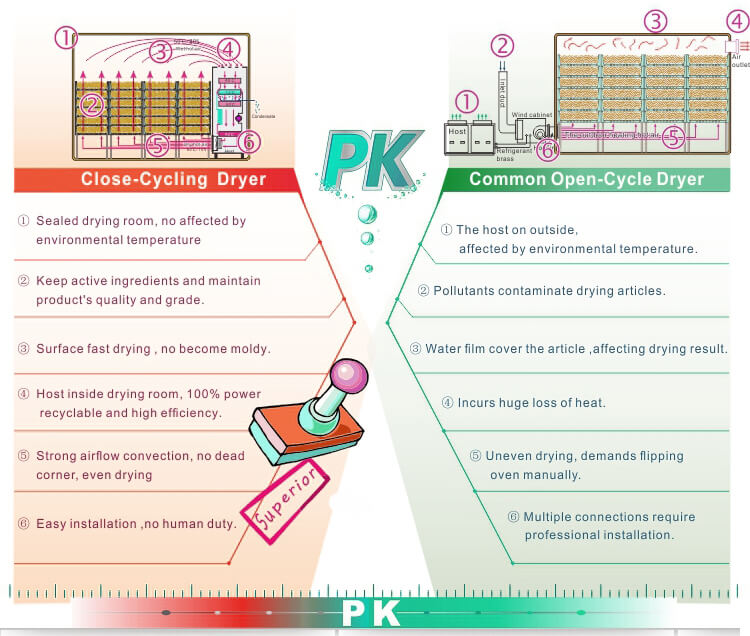

This industrial food drying machine is the professional machine to remove material moisture as quickly as possible at a temperature that does not seriously affect the flavor, texture, and color of the food. The industrial hot air circulation drying machine is featured with axial flow fan, automatic constant temperature control system, and equipped with computer control system for selection.

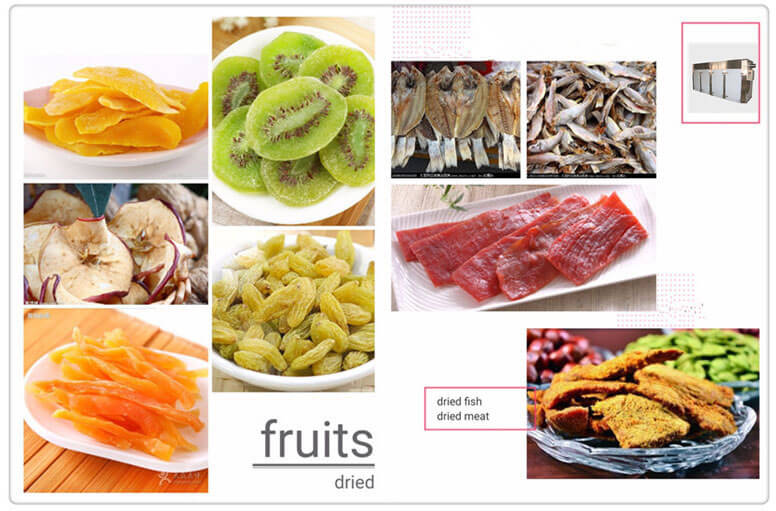

Different from the small hot air drying machines, this large hot air drying machine, featured with more baking vehicles, is suitable for large-scale material drying production. This heat pump drying machine is suitable for drying materials that are mainly resistant to range of temperatures between 20-80 °C during the drying process, such as: wood, grain, seed, edible mushrooms, medicine, seafood, bacon, fruit and vegetables, tobacco leaf, paper and incense, etc.

Spotlights of The Large Hot Air Circulation Food Drying Machine

♦ Reliable and safe operation due to forced ventilation effect, in which there is an adjustable wind board.

♦ Air inlet is equipped with highly efficient air filter and the exhaust event is equipped with medium efficient air filter.

♦ Drying tray made of stainless steel, easy moving, durable and convenient to clean.

♦ Low noise, reliable and safe operation, temperature-controlled, easy installation and maintenance.

♦ Baking timer per batch: 4-6 hours per batch according to different materials.

♦ Wide application: a variety of materials can be dried like vegetables, fruits, herbs, mushroom and etc..

Characteristics of Heat Pump Food Drying Machine

Most hot air is circulated in the drying machine so that heat efficiency is high and the energy is saved. There are adjustable air distribution plates inside the oven. By using the forced ventilation function, the materials can be dried uniformly. The heating source might be steam and electricity. It is a versatile drying equipment that can be used for drying various materials. When you utilize the drying machine, please notice the following tips:

1. When the machine starts to work, if the temperature is too low in the beginning, microorganisms may survive and even grow before the food is adequately dried. If the temperature is too high and the humidity too low, the food may harden on the surface. This makes it more difficult for moisture to escape and the food does not dry properly. So in the drying process, you should pay attention to the temperature.

2. There should be sufficient space among materials on trays so that there is a uniform distribution of heat.

Choose Suitable Plates For The Heat Pump Drying Machine

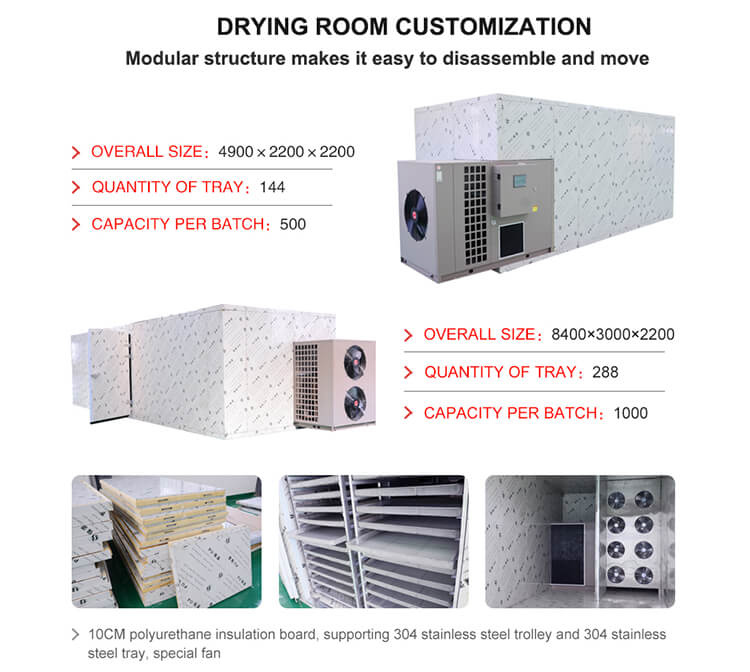

The oven plate also named the oven tray is a significant part of the hot air drying process. There are two types of plates provided by us.

1. PP food grade plastic trays: low cost, suitable for all kinds of materials

2. Stainless steel mesh trays: suitable for higher hygiene requirements

Food Nutritional Changes Occurred During Hot Air Circulation Drying

♦ Calorie content: no change, but is concentrated into a smaller mass as moisture is removed.

♦ Fiber: no change.

♦ Vitamin A: fairly well retained under controlled heat methods.

♦ Vitamin C: mostly destroyed during the drying of vegetables.

♦ Minerals: some may be lost.

♦ Iron: not be destroyed by drying.

Heat Pump Food Drying Machine Video Show

Parameters of the Industrial Heat Pump Drying Machine

I. Dual Circulation Type Food Drying Machines

Ideal Application for Drying Various Flowers, Herbs, Tea, Leaves vegetables, and Tobacco leaves.

| Model | WS-7B | WS-14B |

|---|---|---|

| Heat Pump Power (P) | 7 | 14 |

| Drying Chamber Size (L×W×H)(m) |

4.9×2.9×2.15 | 7.1×2.9×2.175 |

| Circulation Air Fans (kw×Qty) |

0.37×12 | 0.55×12 |

| Electric Auxiliary Power (kw) |

20 | 24 |

| Dehumidification Fan (kw) |

0.55 | 1.1 |

| Trolley Qty (sets) | 6 | 10 |

| Trays Qty (pcs) | 192 | 320 |

II. Air Blowing From Below Type Food Drying Machines

Ideal Application for Drying Various Fruit, Vegetable, Spices, Edible Fungi, Seafood, Meat. Like Fruit Slices, Apple Slices, Lemon, Mango, Pineapple, Grapes, Mushrooms, Chili, Ginger, sweet potato strips, Bacon, etc.

Ideal Application for Drying Various Fruit, Vegetable, Spices, Edible Fungi, Seafood, Meat. Like Fruit Slices, Apple Slices, Lemon, Mango, Pineapple, Grapes, Mushrooms, Chili, Ginger, sweet potato strips, Bacon, etc.

| Model | XC-7B | XC-14B | XC-20B | XC-28B |

|---|---|---|---|---|

| Heat Pump Power (P) | 7 | 14 | 20 | 28 |

| Drying Chamber Size (L×W×H)(m) |

5.1×3×2.6 | 6.7×3×2.6 | 8.1×3×2.6 | 10.5×3.2×2.7 |

| Circulation Air Fans (KW×Qty) |

0.75×9 | 1.1×9 | 1.5×9 | 2.2×9 |

| Electric Auxiliary Power (KW) |

20 | 36 | 36 | 36 |

| Dehumidification Fan (KW) |

0.55 | 0.75 | 0.75 | 0.75 |

| Trolley Qty (sets) | 6 | 9 | 12 | 15 |

| Trays Qty (pcs) | 192 | 288 | 384 | 480 |

III. Air Blowing From Top Type Food Drying Machines

Ideal Application for Drying Various Leaves vegetables, Tea, Flowers, Herbs, Edible Fungi, and Tobacco leaves.

| Model | SC-7B | SC-14B |

|---|---|---|

| Heat Pump Power (P) | 7 | 14 |

| Drying Chamber Size (L×W×H)(m) |

4.7×3×2.55 | 6×3×2.55 |

| Circulation Air Fans (KW×Qty) |

0.75×4 | 1.1×4 |

| Electric Auxiliary Power (KW) |

18 | 20 |

| Dehumidification Fan (KW) |

0.75 | 0.75 |

| Trolley Qty (sets) | 6 | 9 |

| Trays Qty (pcs) | 192 | 288 |